| |

In 1958

the Low Pressure (LP) boilers were still in situ but when I returned in

the summer of 1959 after eleven months at the apprentice training school,

East Yelland, they had been removed. The remaining installed boiler

capacity was sufficient for the installed turbine capacity with just a

minor adjustment. A pressure

reducing range between the HP boilers and LP turbines had been installed.

There was already a steam pressure reducing range between the MP boilers and LP turbines. |

| |

|

| |

The LP Stirling boilers constructed between 1920 and 1923 as

part of the AC station were numbered 5,6,7 & 8 and the

steam turbines nos. 3 & 4. Boilers 1 to 4 formed the original DC

generating station. Boilers 5-8 with an evaporation rate of 25,000

lbs/hr were chain grate with a

single Induced Fan per pair of boilers which drew the air for combustion through the moving

grate. Coal to the grate was fed via hoppers and chutes but largely

controlled by manual labour and all ash handling was via manually hauled

trolleys on a system of rails - an horrendous dark and sulphurous atmosphere - dirt

was not the word for it. There are no records regarding Boilers 1 to 4 but

they will have been entirely hand fired - a very manual process. |

| |

|

| |

The boiler feed pumps were neat small steam

turbines which were a real piece of machinery requiring virtually no

maintenance. Cooling water to the turbine condensers was fed from the

Number 1 Pump house on the River Teign. The cooling water was returned

further down stream to the River Teign. |

| |

|

| |

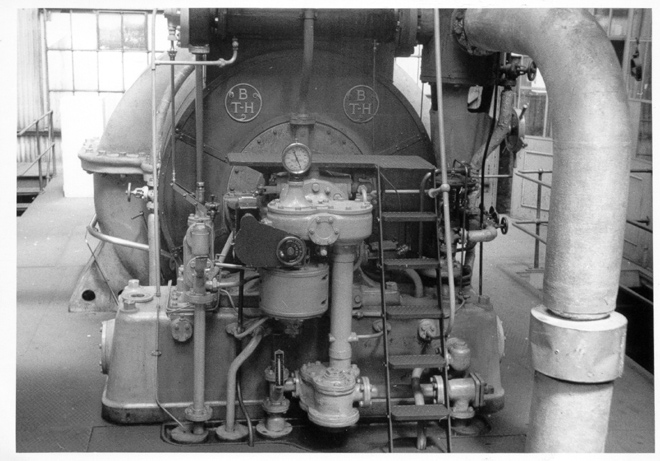

The turbine operating steam pressure was 150 psi

with the boilers and steam range target being 165 psi at 540 deg F (282

deg C). The turbines were

3000 rpm British Thomson-Houston (BTH) and rated at 3750 kw connected at 11,000

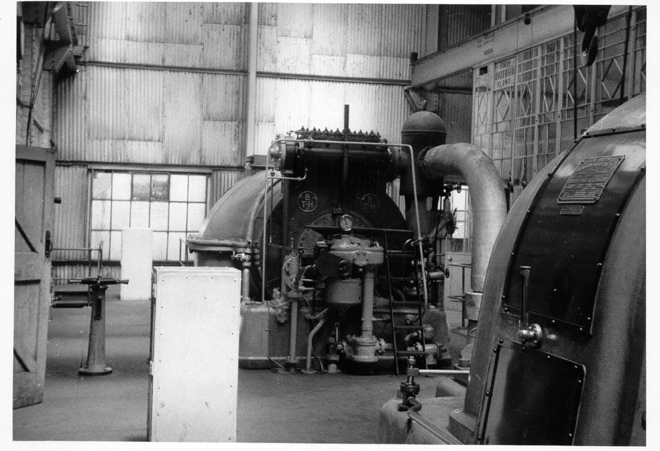

volts to the cellular switchboard. In the picture below the Electrical Maintenance

workshop was behind the windows on the left. I suspect this area included

the first control room and below this the 11kv cellular switch gear. |

| |

|

| |

The roof frames in the distance covered the two 400

kw DC

Rotary Convertors and the 500 volt DC Switchboard together with a 500 volt

600 ampere hour battery bank. |

| |

|

| |

|

| |

The LP Turbine Hall - Generators 3 &

4 - Exciter and Alternator end |

| |

|

| |

|

| |

|

| |

|

| |

HP Steam end - Governor Gear and

Speeder motor |

| |

|

| |

Following the removal of the LP boilers the

basement area was converted into a Civil Defence Regional shelter - a serious

concrete structure with is own diesel generator and air conditioning. It

was never used in anger but provided a base for tools and equipment in the

event of a civil emergency. |

| |

|

| |

|